Contactless digital tachometer using 8051.

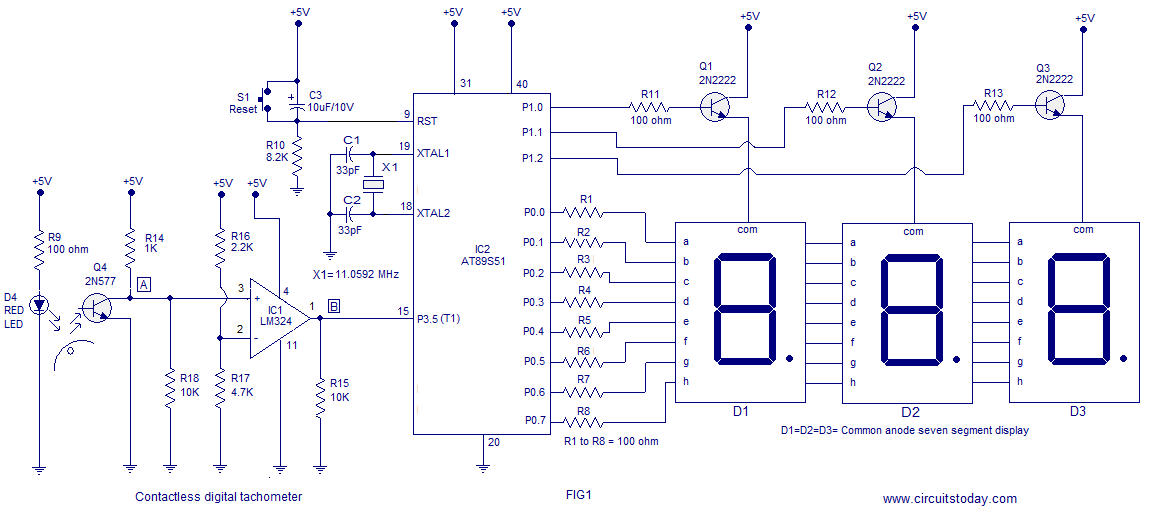

A three digit contact less digital tachometer using 8051 microcontroller which can be used for measuring the revolutions/second of a rotating wheel, disc, shaft or anything like that is introduced in this project. The tachometer can measure up to a maximum of 255 rev/sec at an accuracy of 1 rev/sec. What you just need to do is to align the sensor close to the reflective strip (aluminium foil, white paper or some thing like that) glued on the rotating surface and the meter shows the rev/sec on the display. The circuit diagram of the digital tachometer is shown below.

The first section of the circuit is the optical pickup based on photo transistor Q4 and red LED D4. Every time the reflective stripe on the rotating object passes in front of the sensor assembly, the reflected light falls on the photo transistor which makes it conduct more and as a result its collector voltage drops towards zero. When viewed through an oscilloscope the collector waveform of the photo transistor Q4 (2N5777) would look like this:

From the above two graphs you can see that the negative going edge of the waveform indicates the passage of the reflective patch across the sensor and that means one revolution. If you could some how measure the number of negative going edges occurring in one second, then that’s the rev/sec of the rotating object and that’s what the microcontroller does here.

The 8051 microcontroller here does two jobs and they are:

1) Count the number of negative going pulses available at its T1 pin (pin15).

2) Do necessary mathematics and display the count on the 3 digit 7 segment display.

For the counting purpose both the timers of 8051 (Timer0 and Timer1) are used. Timer 1 is configured as an 8 bit auto reload counter for registering the number of incoming zero going pulses and Timer0 is configured as a 16 bit timer which generate the necessary 1 second time span for the Timer1 to count.

Program.

ORG 000H MOV DPTR,#LUT // moves the addres of LUT to DPTR

MOV P1,#00000000B // Sets P1 as an output port

MOV P0,#00000000B // Sets P0 as an output port MAIN: MOV R6,#14D SETB P3.5 MOV TMOD,#01100001B // Sets Timer1 as Mode2 counter & Timer0 as Mode1 timer MOV TL1,#00000000B //loads initial value to TL1

MOV TH1,#00000000B //loads initial value to TL1 SETB TR1 // starts timer(counter) 1 BACK: MOV TH0,#00000000B //loads initial value to TH0 MOV TL0,#00000000B //loads initial value to TL0 SETB TR0 //starts timer 0 HERE: JNB TF0,HERE // checks for Timer 0 roll over

CLR TR0 // stops Timer0

CLR TF0 // clears Timer Flag 0 DJNZ R6,BACK CLR TR1 // stops Timer(counter)1

CLR TF0 // clears Timer Flag 0

CLR TF1 // clears Timer Flag 1 ACALL DLOOP // Calls subroutine DLOOP for displaying the count SJMP MAIN // jumps back to the main loop DLOOP: MOV R5,#100D BACK1: MOV A,TL1 // loads the current count to the accumulator

MOV B,#100D

DIV AB // isolates the first digit of the count

SETB P1.0

ACALL DISPLAY // converts the 1st digit to 7 seg pattern

MOV P0,A // puts the pattern to Port 0

ACALL DELAY // 1mS delay

ACALL DELAY

MOV A,B

MOV B,#10D

DIV AB // isolates the secong digit of the count

CLR P1.0

SETB P1.1

ACALL DISPLAY // converts the 2nd digit to 7 seg pattern

MOV P0,A

ACALL DELAY

ACALL DELAY

MOV A,B // moves the last digit of the count to accumulator

CLR P1.1

SETB P1.2

ACALL DISPLAY // converts the 3rd digit to 7 seg pattern

MOV P0,A

ACALL DELAY

ACALL DELAY CLR P1.2 DJNZ R5,BACK1 // repeats the subroutine

DLOOP 100 times

RET

DELAY: MOV R7,#250D // 1mS

delay DEL1:

DJNZ R7,DEL1

RET DISPLAY: MOVC A,@A+DPTR // gets 7 seg digit drive pattern for current value in A CPL A // (See Note 1)

RET LUT: DB 3FH // Look up table (LUT) starts here DB

06H

DB

5BH

DB

4FH

DB

66H

DB

6DH

DB

7DH

DB

07H

DB

7FH

DB

6FHEND

Notes.

1) The LUT used here was made for a common cathode seven segment display (used in previous projects) and here we are using a common anode display. The instruction CPL A will just complement the digit drive pattern in accumulator so that it becomes suitable for the common anode display. This is done just because to save my time but not a text book method. The correct way is to make a dedicated LUT for common anode configuration and aviod the extra CPL A instruction.

2) LM324 is a quad opamp and only one opamp inside it is used here. I used LM324 just because that was the only single supply opamp with me at the time. You can use any single supply opamp that matches our supply voltage(5V). You can even use a dual supply opamp (like the popular 741) in single supply mode (+V pin connected to positive supply and -V pin connected to ground) but i wont recommend it unless you have an oscilloscope. Dual supply opamps configured in single supply mode will not give results like a dedicated single supply opamp in the same situation.

3) As we saw earlier the Timer 0 which generates the 1 second time span is configured in Mode 1 (16 bit timer). So the maximum it can count is 2^16 and that is 65536. In 8051 the crystal frequency is divided by 12 using an internal network before applying it as a clock for the timer. That means the timer will increment by one for every 1/12th of the crystal frequency. For an 8051 system clocked with a 12MHz crystal the time taken for one timer increment will be 1µS (ie; 1/12MHz). So the maximum time delay that can be obtained using one session of the timer will be 65536µS and it is looped 14 times to get the 1 second delay. Go through this article Delay using 8051 timer for a better grasp.

4) Also read this article Interfacing seven segment display to 8051 before attempting this project.

This is one of the best ways to build the tachometers. Get Detailed view of Tachometer by clicking here.

BalasPadamTQ for visiting

Padam