Ultrasonic range finder using 8051 .

A simple ultrasonic range finder using 8051 microcontroller is presented in this article. This ultrasonic rangefinder can measure distances up to 2.5 meters at an accuracy of 1 centi meter. AT89s51 microcontroller and the ultrasonic transducer module HC-SR04 forms the basis of this circuit. The ultrasonic module sends a signal to the object, then picks up its echo and outputs a wave form whose time period is proportional to the distance. The microcontroller accepts this signal, performs necessary processing and displays the corresponding distance on the 3 digit seven segment display. This circuit finds a lot of application in projects like automotive parking sensors, obstacle warning systems, terrain monitoring robots, industrial distance measurements etc.

HC-SR04 ultrasonic module.

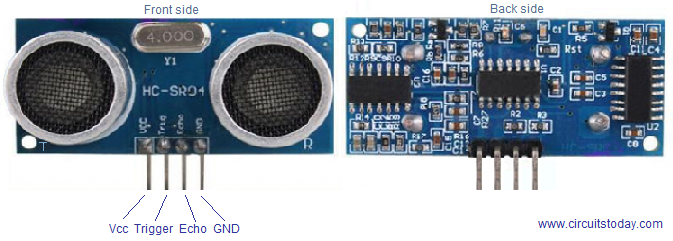

HC-SR04 is an ultrasonic ranging module designed for embedded system projects like this. It has a resolution of 0.3cm and the ranging distance is from 2cm to 500cm. It operates from a 5V DC supply and the standby current is less than 2mA. The module transmits an ultrasonic signal, picks up its echo, measures the time elapsed between the two events and outputs a waveform whose high time is modulated by the measured time which is proportional to the distance. .The photograph of an HC-SR04 module is shown below.

The supporting circuits fabricated on the module makes it almost stand alone and what the programmer need to do is to send a trigger signal to it for initiating transmission and receive the echo signal from it for distance calculation. The HR-SR04 has four pins namely Vcc, Trigger, Echo, GND and they are explained in detail below.

1) VCC : 5V DC supply voltage is connected to this pin.

2) Trigger: The trigger signal for starting the transmission is given to this pin. The trigger signal must be a pulse with 10uS high time. When the module receives a valid trigger signal it issues 8 pulses of 40KHz ultrasonic sound from the transmitter. The echo of this sound is picked by the receiver.

3)Echo: At this pin, the module outputs a waveform with high time proportional to the distance.

4) GND: Ground is connected to this pin.

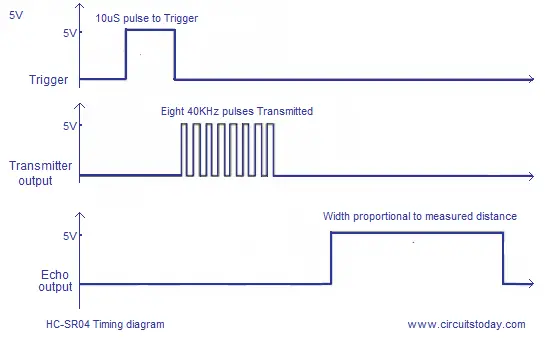

HC-SR04 timing diagram.

From the timing diagram, you can see that the 40KHz pulse train is transmitted just after the 10uS triggering pulse and the echo output is obtained after some more time. The next triggering pulse can be given only after the echo is faded away and this time period is called cycle period. The cycle period for HC-SR04 must not be below 50mS. According to datasheet, the distance can be calculated from the echo pulse width using the following equations.

Distance in cm = echo pulse width in uS/58

Distance in inch = echo pulse width in uS/148

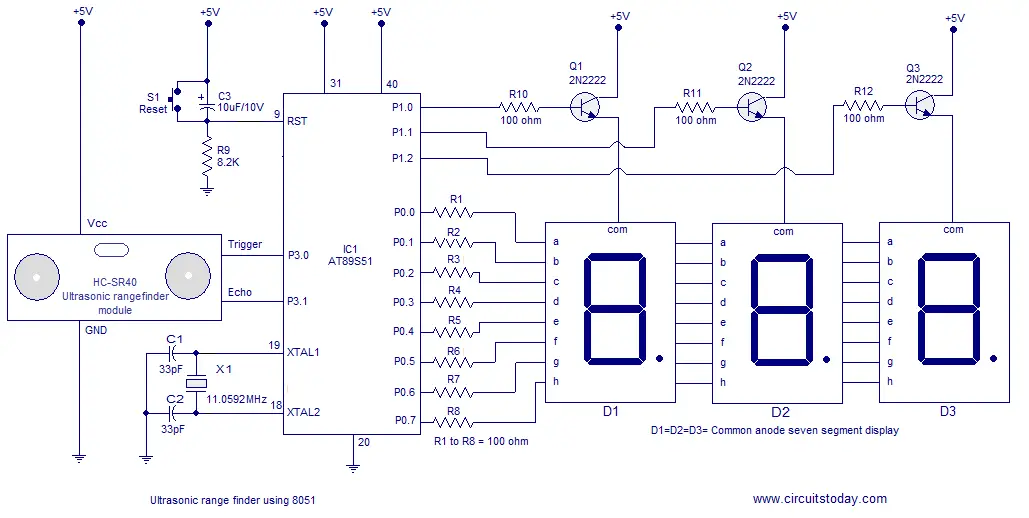

Ultrasonic range finder using 8051- Circuit diagram.

The ultrasonic module is interfaced to the microcontroller through P3.0 and P3.1 pins. Port0 used for transmitting the 8 bit display data to the display and port pins P1.0, P1.1, P1.2 are used for transmitting display drive signals for the corresponding display units D1, D2, D3. Push button switch S1, capacitor C3 and resistor R9 forms a de-bouncing reset circuitry. Capacitors C1,C2 and crystal X1 are associated with the clock circuit.

Program.

ORG 00H // origin

MOV DPTR,#LUT // moves the address of LUT to DPTR

MOV P1,#00000000B // sets P1 as output port

MOV P0,#00000000B // sets P0 as output port

CLR P3.0 // sets P3.0 as output for sending trigger

SETB P3.1 // sets P3.1 as input for receiving echo

MOV TMOD,#00100000B // sets timer1 as mode 2 auto reload timer

MAIN: MOV TL1,#207D // loads the initial value to start counting from

MOV TH1,#207D // loads the reload value

MOV A,#00000000B // clears accumulator

SETB P3.0 // starts the trigger pulse

ACALL DELAY1 // gives 10uS width for the trigger pulse

CLR P3.0 // ends the trigger pulse

HERE: JNB P3.1,HERE // loops here until echo is received

BACK: SETB TR1 // starts the timer1

HERE1: JNB TF1,HERE1 // loops here until timer overflows (ie;48 count)

CLR TR1 // stops the timer

CLR TF1 // clears timer flag 1

INC A // increments A for every timer1 overflow

JB P3.1,BACK // jumps to BACK if echo is still available

MOV R4,A // saves the value of A to R4

ACALL DLOOP // calls the display loop

SJMP MAIN // jumps to MAIN loop

DELAY1: MOV R6,#2D // 10uS delay

LABEL1: DJNZ R6,LABEL1

RET

DLOOP: MOV R5,#100D // loads R5 with 100D

BACK1: MOV A,R4 // loads the value in R4 to A

MOV B,#100D // loads B with 100D

DIV AB // isolates the first digit

SETB P1.0 // activates LED display unit D1

ACALL DISPLAY // calls DISPLAY subroutine

MOV P0,A // moves digit drive pattern for 1st digit to P0

ACALL DELAY // 1mS delay

ACALL DELAY

MOV A,B // moves the remainder of 1st division to A

MOV B,#10D // loads B with 10D

DIV AB // isolates the second digit

CLR P1.0 // deactivates LED display unit D1

SETB P1.1 // activates LED display unit D2

ACALL DISPLAY

MOV P0,A // moves digit drive pattern for 2nd digit to P0

ACALL DELAY

ACALL DELAY

MOV A,B // moves the remainder of 2nd division to A

CLR P1.1 // deactivates LED display unit D2

SETB P1.2 // activates LED display unit D3

ACALL DISPLAY

MOV P0,A // moves the digit drive pattern for 3rd digit to P0

ACALL DELAY

ACALL DELAY

CLR P1.2 // deactivates LED display unit D3

DJNZ R5,BACK1 // repeats the display loop 100 times

RET

DELAY: MOV R7,#250D // 1mS delay

LABEL2: DJNZ R7,LABEL2

RET

DISPLAY: MOVC A,@A+DPTR // gets the digit drive pattern for the content in A

CPL A // complements the digit drive pattern (see Note 1)

RET

LUT: DB 3FH // look up table (LUT) starts here

DB 06H

DB 5BH

DB 4FH

DB 66H

DB 6DH

DB 7DH

DB 07H

DB 7FH

DB 6FH

END

About the program.

The first part of the program sets the initial conditions. Port 0 and P0rt 1 are set as output ports for sending digit drive patterns and digit drive signals respectively. Port pin 3.0 is set as an output pin for sending the trigger signal to the ultrasonic module for starting transmission and port pin 3.1 is set as an input pin for receiving the echo. TMOD register of the microcontroller is so loaded that the Timer 1 operates in mode2 8 bit auto-reload mode. Timer 0 of the microcontroller is not used here. In the next part of the program (loop MAIN) the TL1 and TH1 registers of Timer1 are loaded with the initial values. TL1 is loaded with the initial value to start counting from and TH1 is loaded with the reload value. This is how timer 1 in mode 2 works: When TR1 bit of the TCON register is set the TL1 starts counting from the initial value loaded into it and keeps counting untill roll over (ie; 255D). When roll over occurs, TF1 flag is set and TL1 is automatically loaded with the reload value stored in TH1 and the sequence is repeated until TR1 is made low by the program. The TF1 goes high at the first roll over and if you want it as an indicator for each roll over, you have to clear it using the program after each roll over. In the next part of the MAIN loop P3.0 is set high for 10uS and then cleared to make 10uS triggering pulse. The ultrasonic module issues a 40Khz pulse wave form after receiving this trigger and the program waits until a valid echo is received at P3.1. The pulse width of the echo signal is proportional to the distance to the obstacle and so the next job of the program is to measure the pulse width. Whenever there is a valid echo pulse at P3.1, the Timer1 starts and it counts from the initial value to 255 ie: 255-207= 48 counts. Then the counter restarts and accumulator increments by one for every restart. This sequence is repeated until the echo signal at P3.1 vanishes (ie; P3.1 goes low). Now the content in A will be equal to the number of Timer1 reloads which is in fact proportional to the distance. From the datasheet it is clear that 58uS echo pulse width indicates 1cM distance. When the processor is clocked by a 12MHz crystal, 58 counts of Timer1 indicates 1cM. That means 1 reload is equal to 1cM. But here we are letting the Timer1 to count only 48 times before reload and this is done in order to compensate for the time lags caused by the branching instructions used for checking the status of P3.0 and P3.1 pins. If this trick is not done, the individual time lags cause by the branching instructions will be cumulatively added to the observed pulse width and the range finder will show a reading higher than the original distance. Some trial and error was required for getting the correct Timer1 reload value and with the 207D (ie; 48 counts) used here the error was found to be less than half a centimeter which is quite fine in this context. The next part of the program does necessary mathematics on the current content in A and displays it as 3 digit readout on the display.

Notes.

1) The LUT used here was originally made for a common cathode seven segment display and here we are using common anode displays. The CPL A instruction will just complement the obtained digit drive pattern and make is suitable for the common anode scheme. If you have time ,then cook up an LUT for common anode scheme and replace the current one using it. By this you can avoid the extra CPL A instruction and it is the correct method.

2)The entire circuit can be powered from 5V DC.

3) Be careful while handling the Ultrasonic module. There are a lot of sensitive surface mount devices fabricated on its back side.

4)Go through these articles: Interfacing seven segment display to 8051, Delay using 8051 timer, Software delay routines using 8051.

Tiada ulasan:

Catat Ulasan